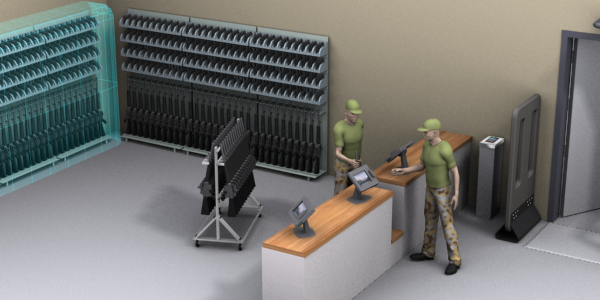

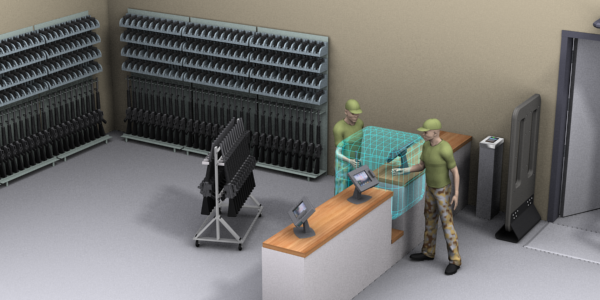

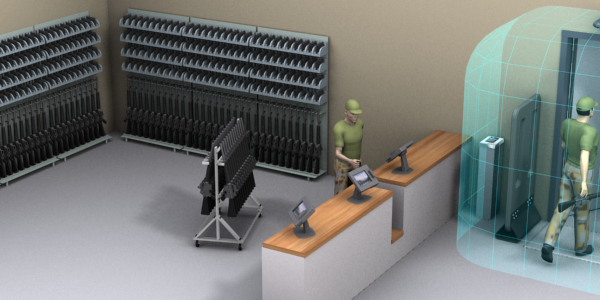

RuBee is an active, wireless, Near Field Communication Automated Identification Technology (AIT) that uses magnetic waves for communication. Developed by US company Visible Assets Inc., RuBee was purpose built for AIT applications and does not use Radio Frequency (RF) fields. RuBee provides peer to peer volumetric communication; it is not a line of sight, which means it is intrinsically safe with ZERO separation distance, capable of being fitted to nuclear warheads, able to operate in confined spaces, such as on ships, inside shipping containers and underwater, etc. This provides significant advantages over Radio Frequency Identification (RFID) and similar communications protocols for AIT applications.

The RuBee protocol is an international wireless standard, IEEE1902.1 and the tags have passed stringent safety and security tests conducted by the US Department of Defence. RuBee tags have a range from 1 to 15 metres and have a very low power demand. The batteries in the small tags can last up to 25 years. RuBee tags can also be fitted with a programmable microprocessor, which represents a significant opportunity to fit other prognostic sensors. In addition to asset identification, the RuBee SuperSensor tags currently enable monitoring of environmental conditions including shock, vibration, temperature, humidity and pressure. A shot counter tag, purpose-built for weapons, can be fitted, which is useful in planning maintenance activities. RuBee uses magnetic fields, has no significant RF energy and has the following advantages: